Material flow rules in SAP Business ByDesign

04.10.2017

SAP offers various process automation options to optimize a complex storage layout in relation to inbound logistics and outbound flows.

The material flow automation can be defined on a superordinate level for all dependent subordinate storage areas or specified for individual storage areas. The latter variant overwrites a possible generic material flow definition on the header level of the storage location. The material flow always refers to the source and destination.

Material flow rules in relation to source describe an automated goods flow of the type outbound logistics into the corresponding storage location or storage area. The outbound logistics can originate from sales orders, relocations, supplier returns and replenishment for production.

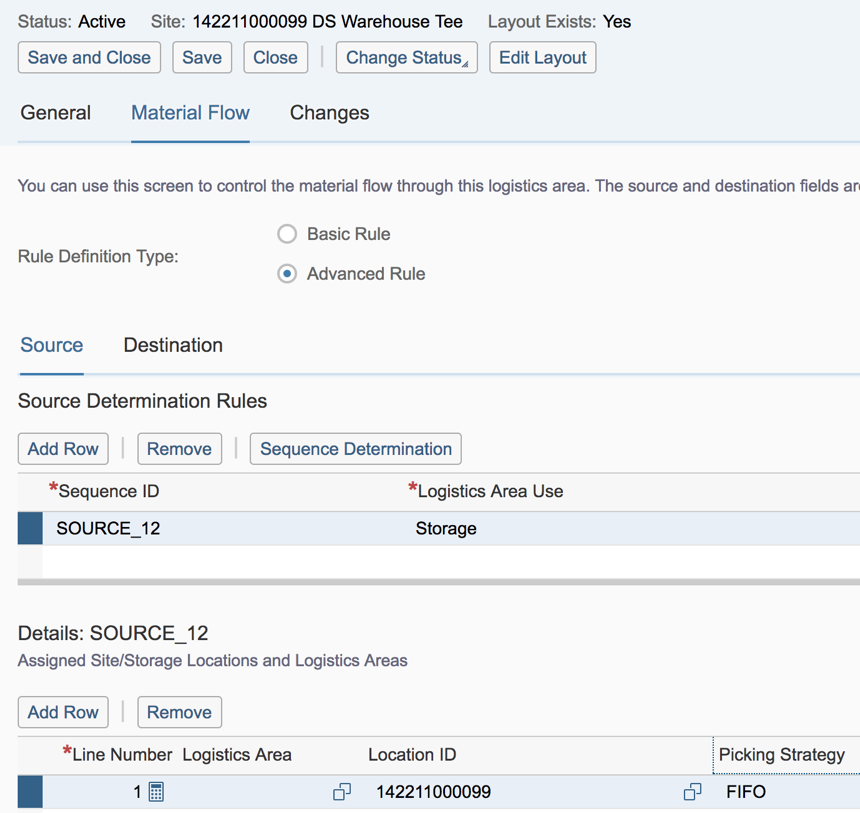

The logistics area use also describes, in relation to source, which logistical use has to be assigned to a subordinate storage location in a storage location activated for the material flow automation so that an inventory of a storage location may also be included for the outbound logistics. The logistics area use is assigned to storage in the screenshot. For the automated outbound logistics rule, this means that the system only selects storage locations where this logistics area use was activated. As a result, specific storage locations can be excluded from the outbound logistics (e.g. QA test store or production and buffer store).

Here the picking strategy describes the procedure according to which the inventory and possibly specific batches are to be picked (e.g. according to FIFO, minimum movement during order picking etc.).

Material flow rules in relation to destination describe an automated goods flow of the type inbound logistics into the corresponding storage location or storage area. Supplier orders, relocations, customer returns or also restorage from production output.

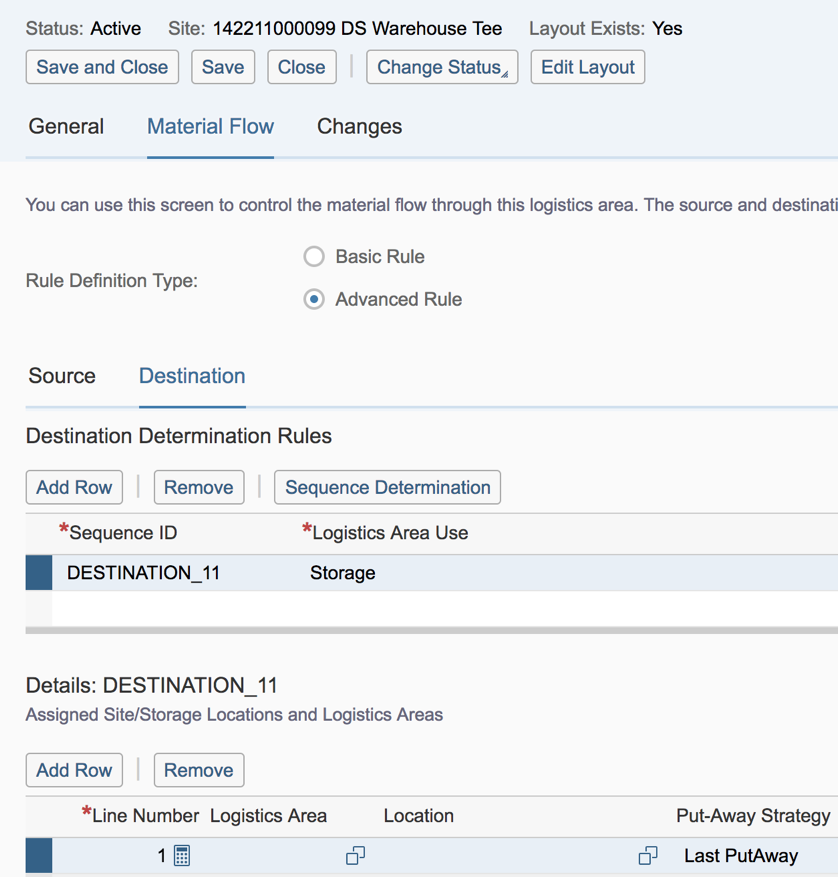

In the case of destination, the logistics area use specifies in which subordinate storage location in a storage location activated for the material flow automation inventories may be put into storage.

The logistics area use is assigned as for source, storage in the screenshot. For the automated inbound logistics rule, this means that the system only selects storage locations where this logistics area use was activated. This prevents products from being put into storage in impermissible areas such as a QA laboratory. Here the put-away strategy describes the procedure according to which the inventory and possibly specific batches are to be put into storage.

Possible inbound storage strategies here are typically “first found storage space”, “last storage space becoming free” (chaotic warehousing) or material controlled. If the material-controlled inbound storage strategy is applied, the system searches according to product, storage group and batch specific rules and checks for each product which subordinate storage space fulfils the conditions for an inbound storage.

The material controlled inbound storage strategy presupposes extensive storage space settings, as it is necessary to define which product is to be put into storage where and whether there are criteria that prevent an inbound storage. Possible scenarios can involve batch-pure storage, identical products separated by owner (e.g. for the internal repair of customer products), inbound storage only on full pallets, only products of a definite storage group (refrigerated products only in cold storage).

Back to overview